InoCoat (IC3)

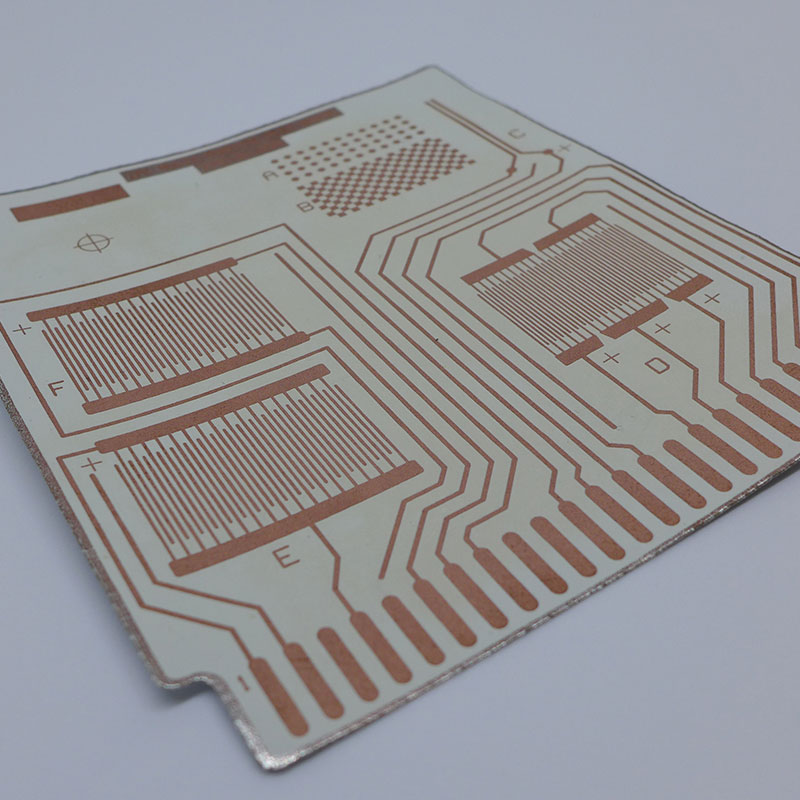

The technology enables the application of all coating materials with a melting point of up to 2000 °C on highly sensitive substrates without damaging them. InoCoat was designed for a minimum floor space requirement and the highest possible output. The sophisticated design of the plasma torch ensures extraordinarily easy and safe maintenance, thus guaranteeing efficient replacement of the wear parts during serial operation.

The plasma torch weighs just 2.4 kg and can thus be used in an extremely flexible manner. Depending on the application, a coating speed of up to 1000 mm/s is achieved, the distance to the substrate is usually between 10 and 60 mm for a spray width of approximately 8 mm for microcoatings and around 80 mm for nanocoatings.

Advantages

Technical data

Further products

Micro Cold Plasma

Plasma plotter

InoFeed

To the applications

Functionalisation

Corrosion protection

Activation (MCP)

Plasma cleaning

To the projects

If this appeals to you, send us your application and become part of our team.