Special mechanical engineering

Focussed on your success

From fully automated production lines to welding technology through to surface activation and functionalisation, you are in good hands with us!

One-Stop-Shop

Due to our many years of experience in the areas of engineering, design, automation technology, electrical assembly and mechanical assembly, we are able to solve all details in-house. Production, assembly and customer acceptance are performed in our in-house production and assembly facilities.

Commissioning and after-sales support are also carried out by our highly competent employees.

To the projects

Our competencies

Robotics

As the robots are very versatile, they can be used on the entire production line or assembly line for tasks such as welding, painting, cutting and in-line inspection.

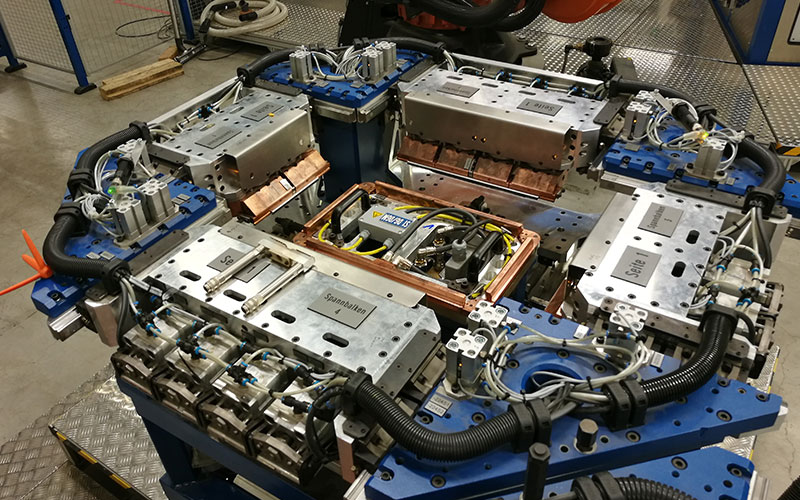

Clamping technology

We also focus here on chucking tools Different dimensions and different types of workpiece are possible in our production cells.

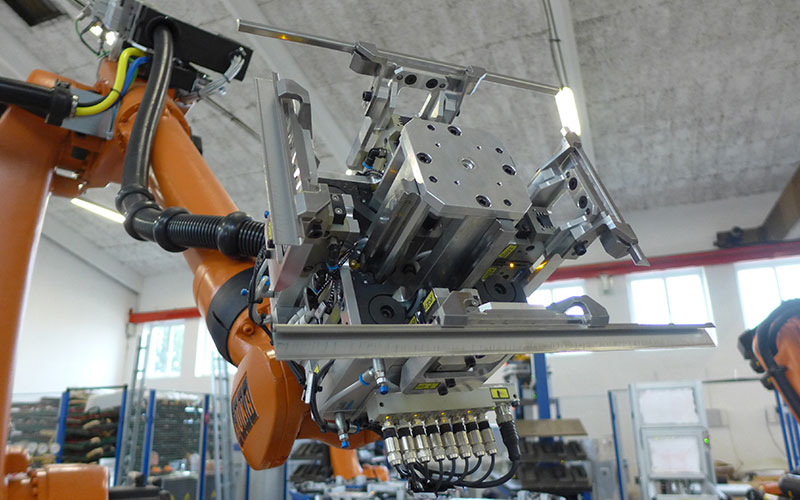

Gripper technology

In each case, we select the optimal technology for our customers to suit the task at hand.

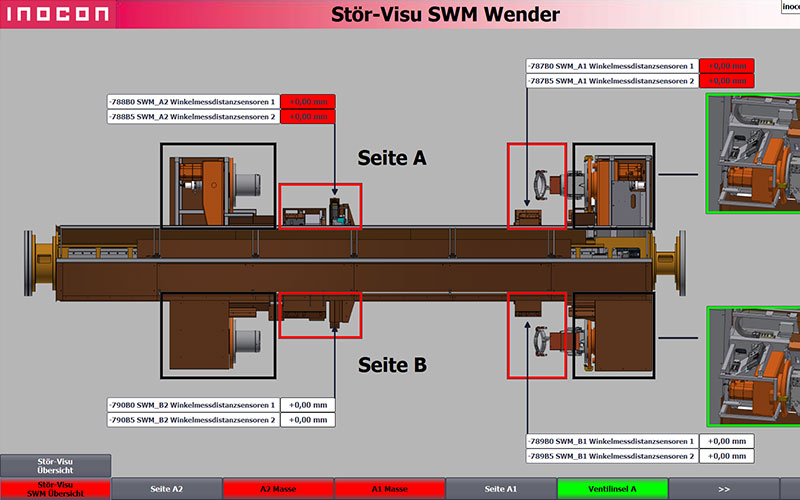

Programming

Our services

R&D

Sampling

Design

Automation

Production

Assembly

Commissioning

After-Sales

Research and development

INOCON Technologie GmbH is involved in industry-oriented research in a series of national and international research projects.

The focus is on atmospheric plasma applications for coating, cleaning, activation and welding.

These in-line processes are suitable for local or large-scale functionalisation of 2D or 3D substrates or for additive manufacturing or complex welding tasks.

We are happy to try out new tasks in our test laboratory and support you in the implementation of your project idea.

Sampling

In our test laboratory, we carry out the validation of customer requests with the following technologies:

- Plasmatron

- MIG/MAG

- Plasma

- Atmospheric coatings

- Surface activation

The evaluation of the results and a complete report are available as standard for our customers.

Design

INOCON Technologie GmbH is your reliable partner for the planning, simulation and implementation of your complex tasks. For this purpose, we use commercial 3D CAD software (Autodesk Inventor Professional) for the creation of single parts, assemblies and complete systems in accordance with national and international standards.

In the design phase, ergonomic and design-critical aspects are examined in addition to functional aspects.

Automation

INOCON Technologie GmbH is your specialist in the area of modern automation technology. For this purpose, we cover – depending on the customer vision – all automation stages from operator-based small-scale manufacture to fully automated plants.

We would be delighted to advise you on a possible level of automation for your plant and thus achieve an optimal overall concept.

Production

Mechanical production is an important supplement to special-purpose machine construction for INOCON Technologie GmbH. The use of project-specific production enables plant-relevant components, single parts, connecting pieces, etc. to be produced quickly and efficiently with high accuracy. Potentially long waiting times can thus be avoided and adaptations or expansions to your plant can be processed quickly.

Assembly

Plant assembly on site at INOCON Technologie GmbH or directly on the customer’s premises is an important element of our service chain. Our assembly team works quickly and reliably and will support you with regard to any questions and challenges that arise at the plant location.

Commissioning

Commissioning is a special moment both for us and our customers. INOCON Technologie GmbH will support you in the commissioning and the rapid integration and use of the plant for serial production.

We are happy to support you with our technical expertise, e.g. in the area of gripper, welding or coating technology in the initial production phases.

After Sales

Our support starts with the conclusion of the contract The engineers of INOCON Technologie GmbH are happy to support you regarding your requests and process-related challenges. We are also open to accompanying you further after the successful commissioning in order to monitor and optimise your production process. In addition to the range of wear parts or additives, we offer a series of modular standard products for increasing the efficiency of your processes.

To the projects

If this appeals to you, send us your application and become part of our team.