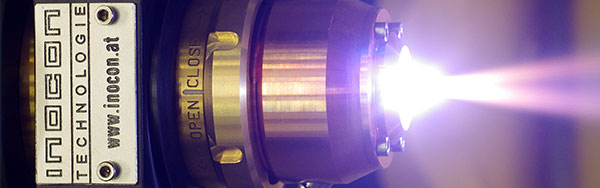

InoFeed

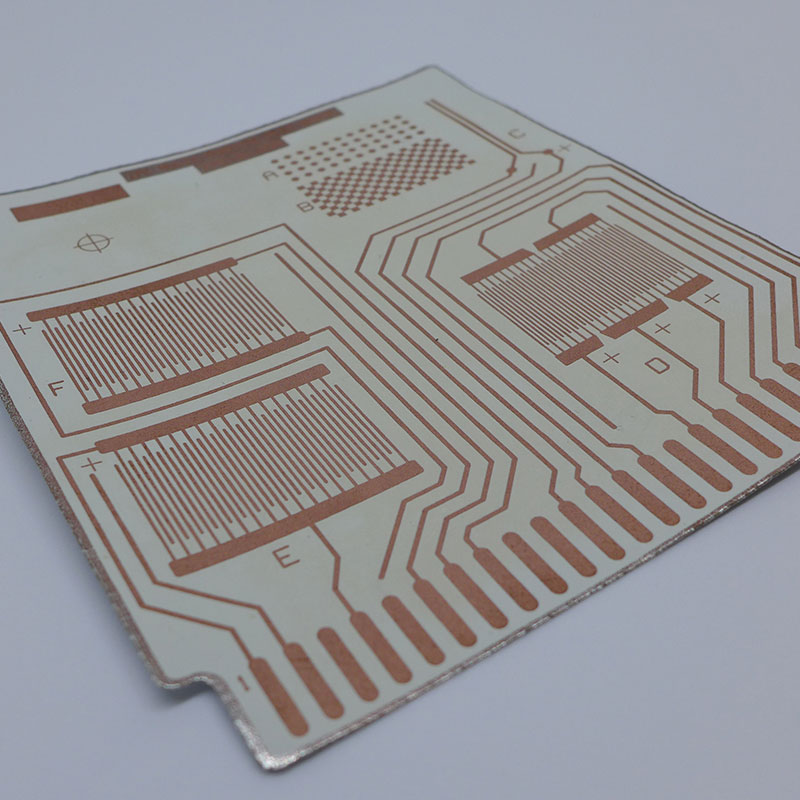

InoFeed and TwinoFeed are powder feeders developed by INOCON for the plasma coating process. For this purpose, exchangeable stainless steel cartridges (127 ml) are filled with micro-powders and fed into the plasma process via a feed motor and a stainless steel brush. This low-maintenance supply process promises constant powder delivery quantities and, as a result, consistent coating results. The optimised dispersion head seal prevents particulate leakage from the flange surface and ensures a clean and stable process workflow. The delivery parameters can be optimised to suit the powder composition and the material properties.

Advantages

High reproducibility and accuracy of the delivered powder quantity

High coating efficiency due to the tandem powder delivery

Efficient production of gradient coatings

Use of flake-shaped or polyhedron-shaped powder grains

Smooth delivery of small grain sizes<<1 μm

Simple process integration capability

Short powder inlet phases

Technical data

Model

Cartridge magazine

Process gases

Supply

Length (mm)

Width (mm)

Height (mm)

Weight (kg)

InoFeed

4

Argon, compressed air, nitrogen, forming gas N2/H2:95/5

24V DC

850

800

1650

205

TwinoFeed

8

Argon, compressed air, nitrogen, forming gas N2/H2:95/5

24V DC

1915

1160

1555

360

Further products

InoCoat

Micro Cold Plasma

Plasma plotter

To the applications

Functionalisation

Corrosion protection

Activation (MCP)

Plasma cleaning

To the projects

Corresponding case studies and reference projects can be found described in the projects.

Developing and applying technologies and creating customer solutions.

If this appeals to you, send us your application and become part of our team.