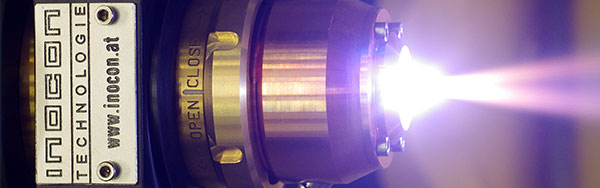

Micro Cold Plasma (MCP)

Activation or cleaning is often essential where materials or surfaces have to be bonded or painted. The reason for this is the insufficient free surface energy or poor wettability.

This is where plasma pretreatment via the Micro Cold Plasma (MCP) system of INOCON comes into play. The atmospheric MCP technology enables the careful cleaning and activation of surfaces without damaging them. The pretreatment is particularly effective on very nonpolar materials – such as plastics. However, a surface modification in the form of better wettability can also be detected in materials that are less nonpolar, such as metals.

Advantages

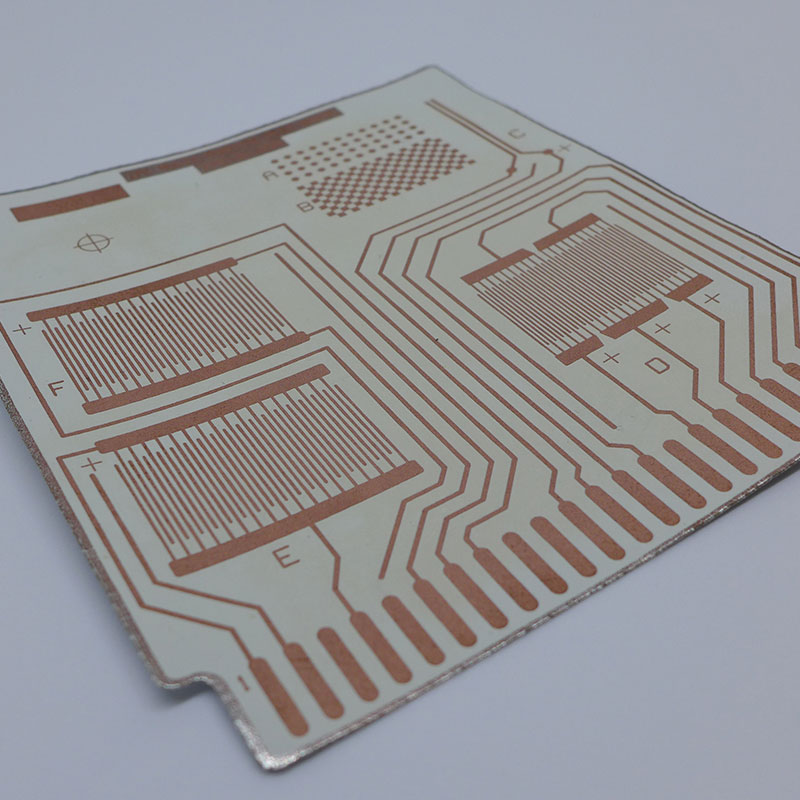

Plasma cleaning and activation of sensitive substrates (e.g. plastics)

Activation width >60 mm

Low process costs

Compact design (torch, power electronics)

Technical data

Model

max. Power (kW)

Process gas

Length (mm)

Width (mm)

Height (mm)

Weight (kg)

MCP 500

0,5

Compressed air

50

50

260

0,8

MCP 2000

2

Compressed air

50

50

260

0,8

Further products

InoCoat

Plasma plotter

InoFeed

To the applications

Functionalisation

Corrosion protection

Enable (MCP)

Plasma cleaning

To the projects

Corresponding case studies and reference projects can be found described in the projects.

Developing and applying technologies and creating customer solutions.

If this appeals to you, send us your application and become part of our team.