Plasma plotter

The production of coating systems in combination with our atmospheric coating process is another core competence of our company. This means that we offer a very wide range of coating variants available to our costumers.

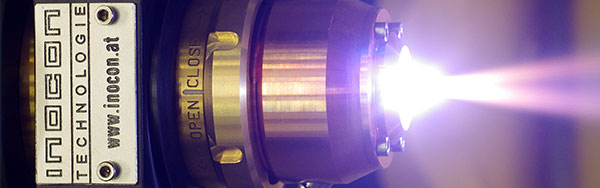

The plasma plotter is a complete coating system for highly diverse challenges. The plasma plotter is a complete coating system for highly diverse challenges. The system has been designed as a “plug & play” solution and offers added value for complex research projects and for production-oriented applications. Due to the diversified application options, there are different workpiece carrier systems. Depending on what is used, either the lightweight, compact plasma torch or the substrate is moved.

Advantages

Combination of different coating methods

Visualisation of all machine components and process monitoring

Parameter storage

Interfaces for data import and data export

Simple motion control and programming

Different models available (standard, 3D, R2R, etc.)

Technical data

Model

for coating process

max. Amperage (A)

Compressed air

Supply

Motion control

Plasma plotter

Standard

Standard

InoCoat 3, MCP

350

6bar DIN ISO 8573-1 Class 3

3x 400V/64A

Burner by means of X-Y handling

Plasma plotter

Volume

Volume

InoCoat 3, MCP

350

6bar DIN ISO 8573-1 Class 3

3x 400V/64A

Substrates by means of X-Y handling or roll to roll

Plasma plotter

3D

3D

InoCoat 3, MCP

350

6bar DIN ISO 8573-1 Class 3

3x 400V/64A

Substrate using a robot

Further products

InoCoat

Micro Cold Plasma

InoFeed

To the applications

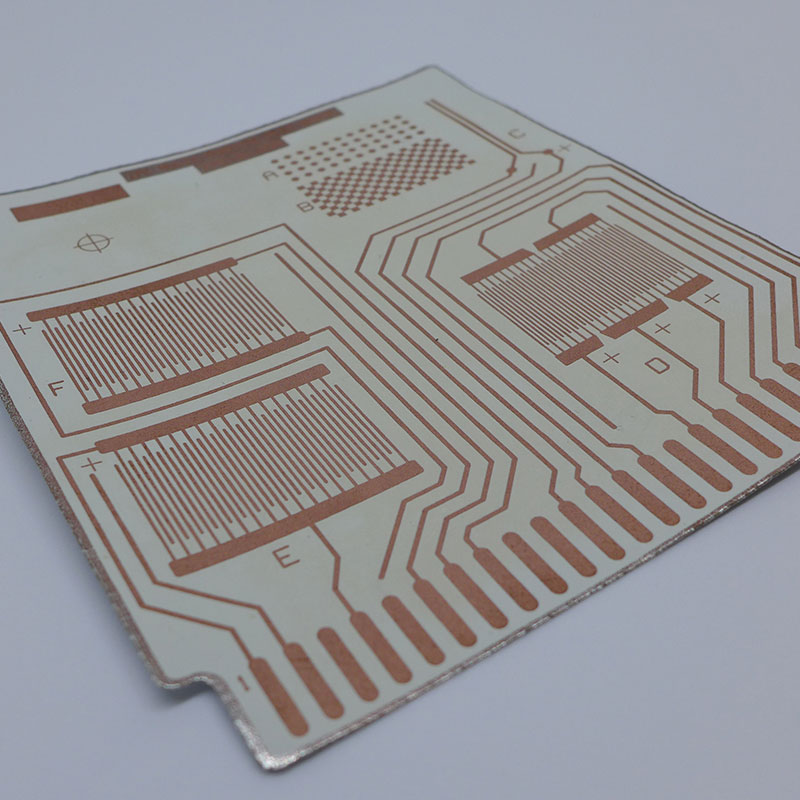

Functionalisation

Corrosion protection

Enable (MCP)

Plasma cleaning

To the projects

Corresponding case studies and reference projects can be found described in the projects.

Developing and applying technologies and creating customer solutions.

If this appeals to you, send us your application and become part of our team.