Welding technology

Focussed on your success

With over 25 years of welding experience and successfully implemented projects that range from automotive customers and their suppliers to kitchen appliance manufacturers, INOCON offers weld seam developments for your components.

We are happy to accept your challenges in terms of cycle time and seam appearance as well as complex geometries and special materials.

Welding laboratory

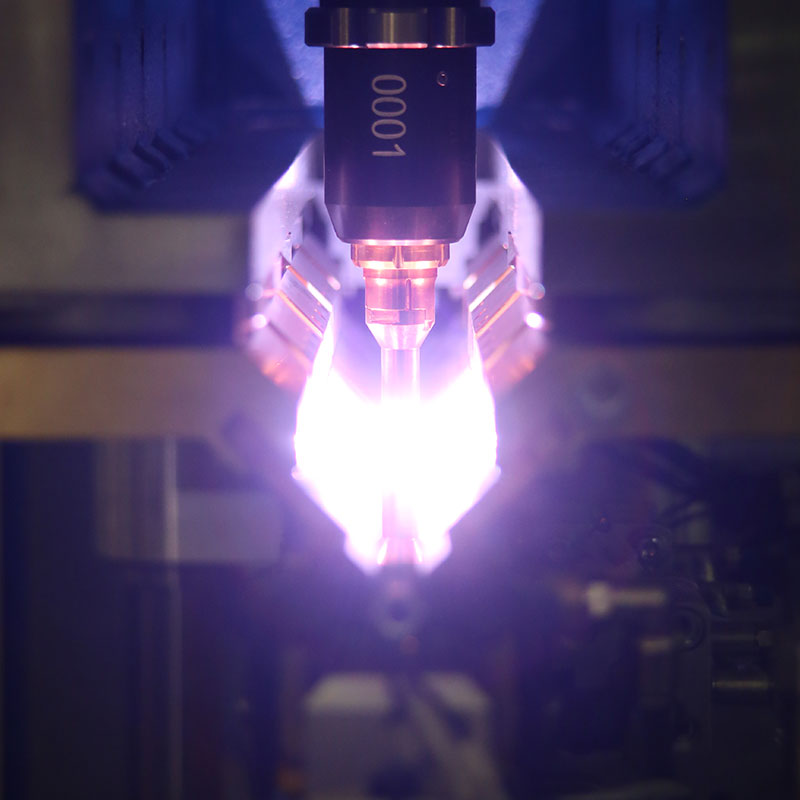

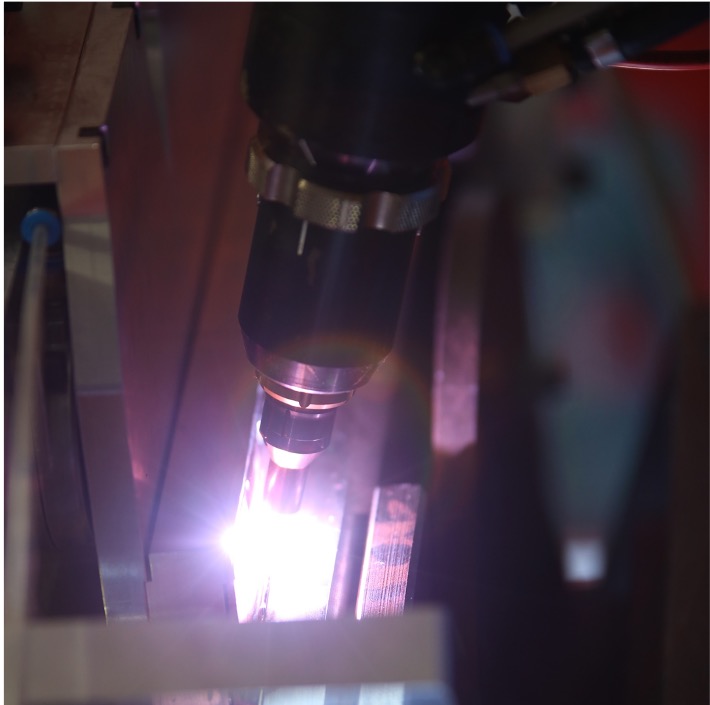

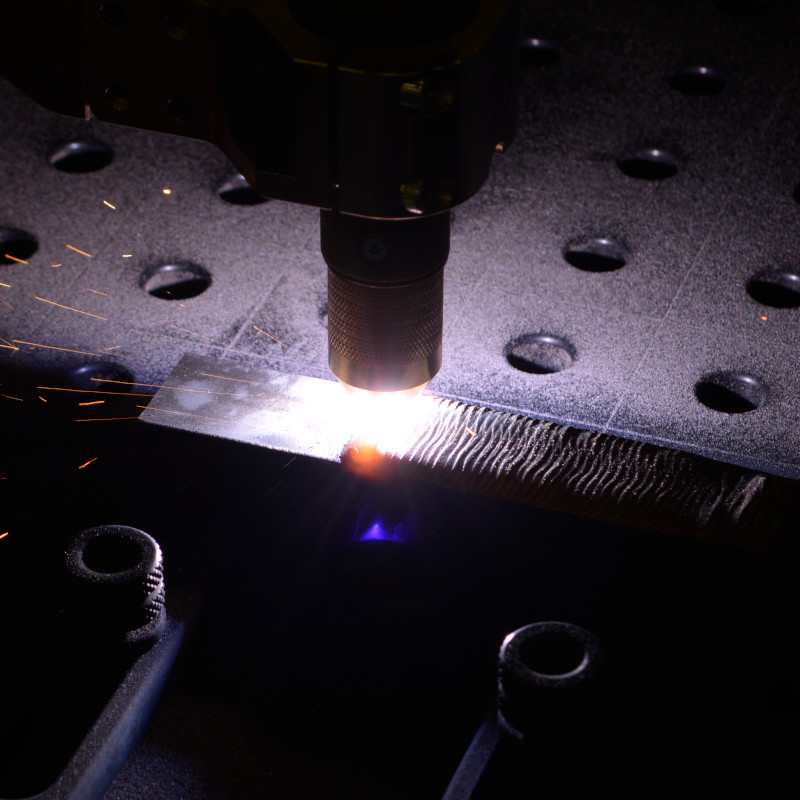

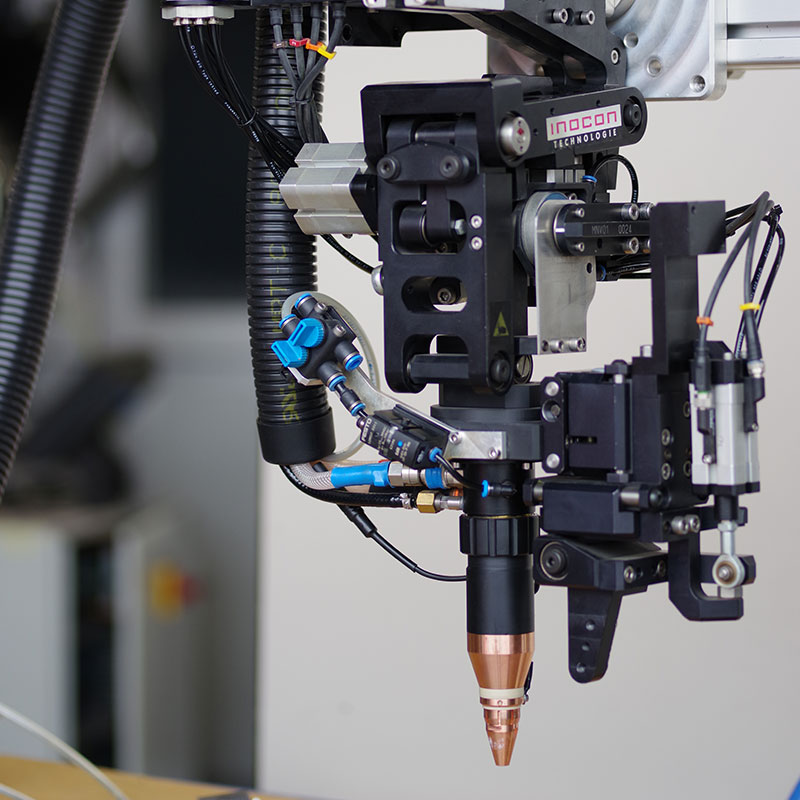

In the welding laboratory, we can simulate the following welding processes on 4 robots: Plasmatron, plasma as well as MIG / MAG. We then analyse the test welds in-house and produce microsections in order to evaluate the weld seam.

Since we know just how important clamping technology is for the weld seam, we can design more complex jigs and fixtures in CAD, and also produce these for you. Our expertise in complex clamping technology has already been demonstrated in many automated installations.

Plasmatron

Plasma

MIG / MAG

Plasmatron torch

Seam guidance

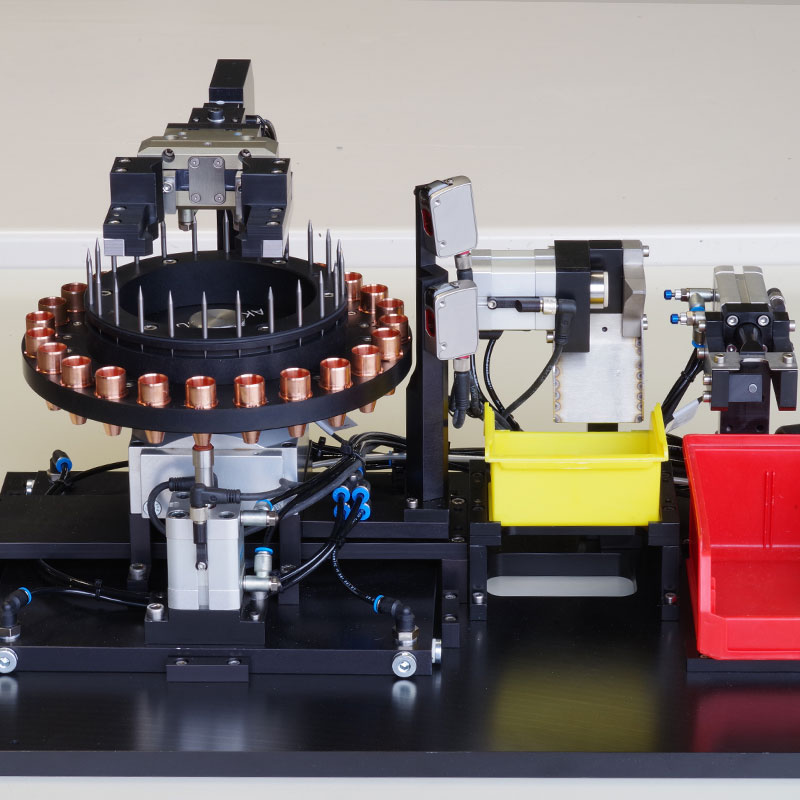

Cathode changer

To the projects

If this appeals to you, send us your application and become part of our team.