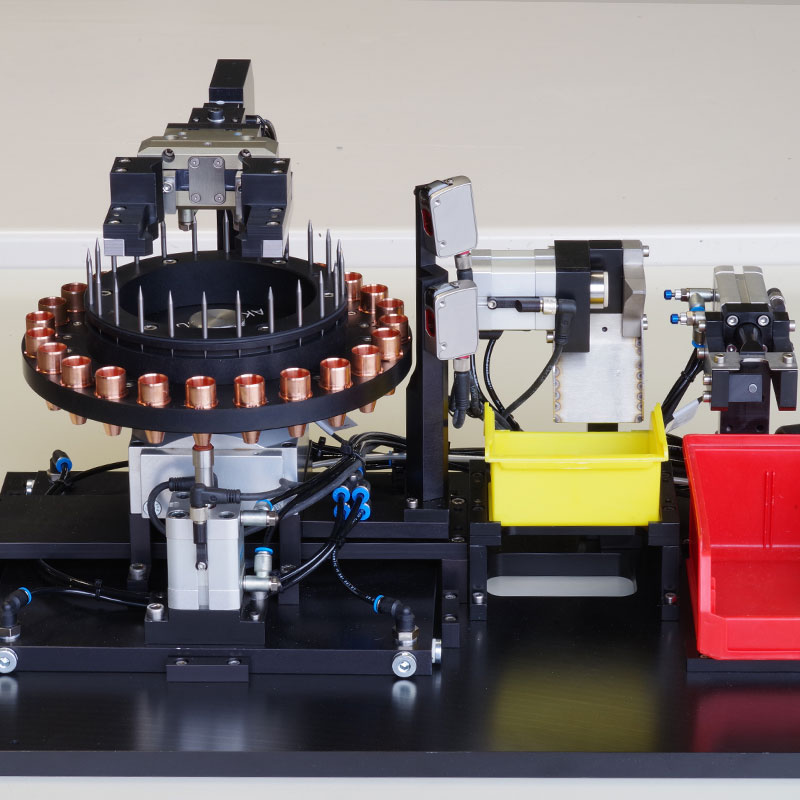

Cathode changer

Focussed on your success

Replacing wear parts on a production line is often time consuming and leads to production downtimes.

The AKS automatic cathode changing system was developed with a view to an ever improving degree of automation and productivity and ensures rapid, fully automatic cathode and nozzle replacement for the Plasmatron.

When the wear limit is reached, the welding robot enters the ACS and replaces the Plasmatron wear parts in less than 15 seconds.

Downtimes of the plant can thus be minimised and productivity increased.

Advantages

Reduces the production interruptions required for maintenance

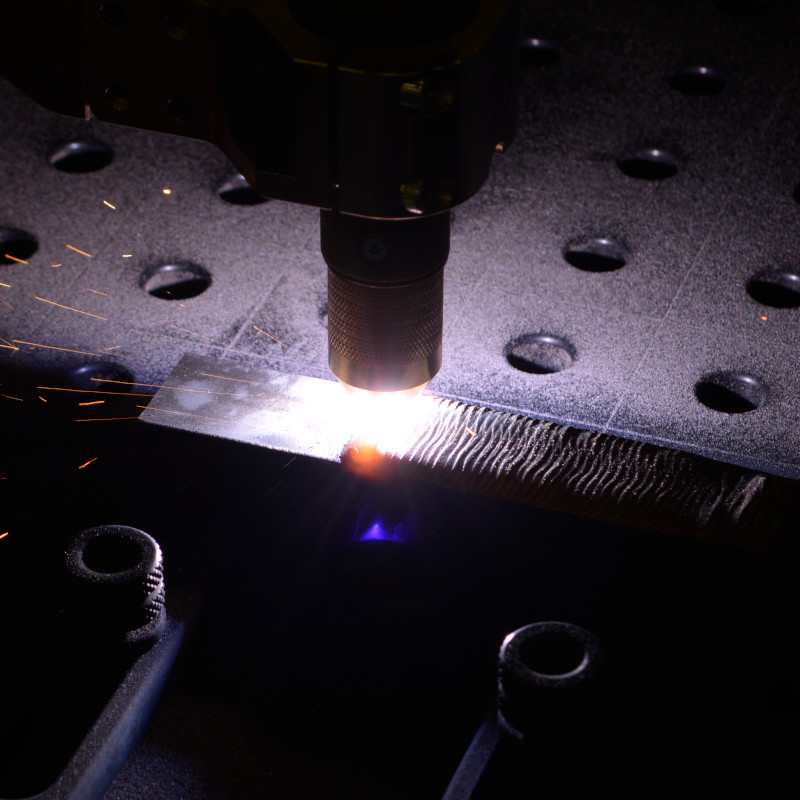

Reproducible installation of wear parts preserves the quality of the weld seam

Lower production costs

Reduction of operating and wear costs

Integrated, adaptable interface to the handling device

Technical data

Model

for welding process

Cathode magazine

Nozzle magazine

Robot accuracy

Compressed air

Supply

Length (mm)

Width (mm)

Height (mm)

Weight (kg)

AKS02-000-995

Plasmatron

24

24

+/-0.15mm

6bar

24V DC

525

380

551

26

AKS02-000-991

Plasmatron

24

24

+/-1.0mm

6bar

24V DC

525

380

617

30

Further products

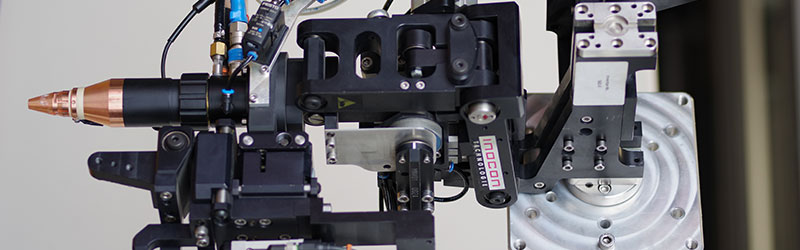

Plasmatron torch

Seam guidance

About the procedures

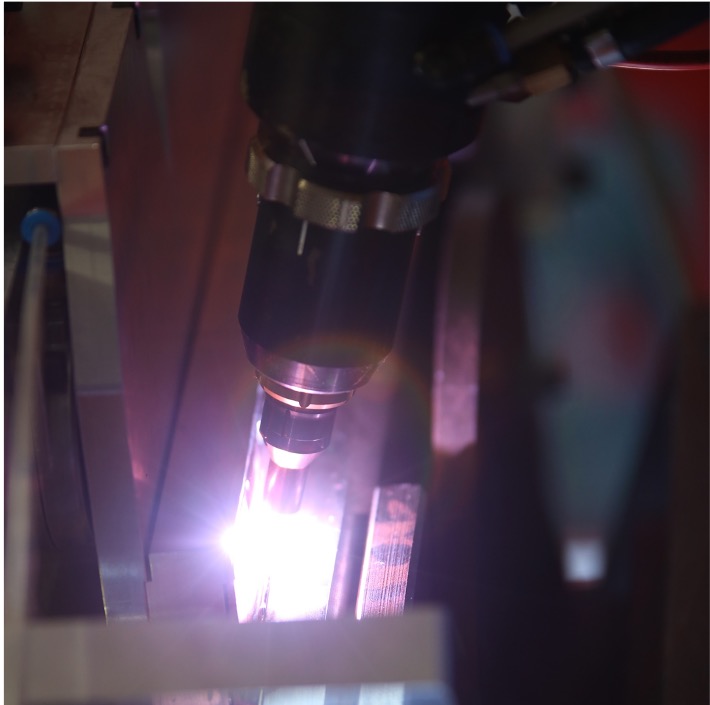

Plasmatron

Plasma

MIG / MAG

To the projects

Corresponding case studies and reference projects can be found described in the projects.

Developing and applying technologies and creating customer solutions.

If this appeals to you, send us your application and become part of our team.