MIG / MAG

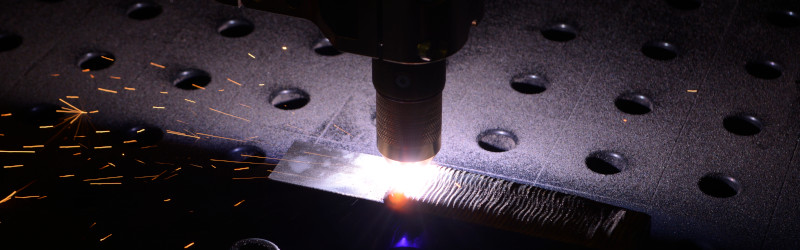

MAG welding is one of the shielding gas metal arc welding processes, in which a wire electrode is melted under a shielding gas.

During MAG welding, the permanent connection of metals is achieved via high heat input and auxiliary welding materials. The heat input for the fusion welding process is created by an electric arc. The wire electrode used flows as a filler wire together with the melted base material and contributes to the formation of the weld seam.

The method is characterised by high processing speeds, is regarded as extremely robust and offers the option of automation.

The MAG process is therefore particularly suitable for industrial applications involving robots or manual work.

Advantages:

Application areas:

MAG welding is probably the most common welding process and can be used for almost all materials.

High welding speeds:

During MAG welding, high welding speeds can be achieved due to the high melting rate.

Gap bridging ability:

Due to the use of very high wire feed rates, gaps or component tolerances can be compensated.

Robust:

MAG welding is considered to be a very robust process and can also be used in very harsh environments.

Additional methods

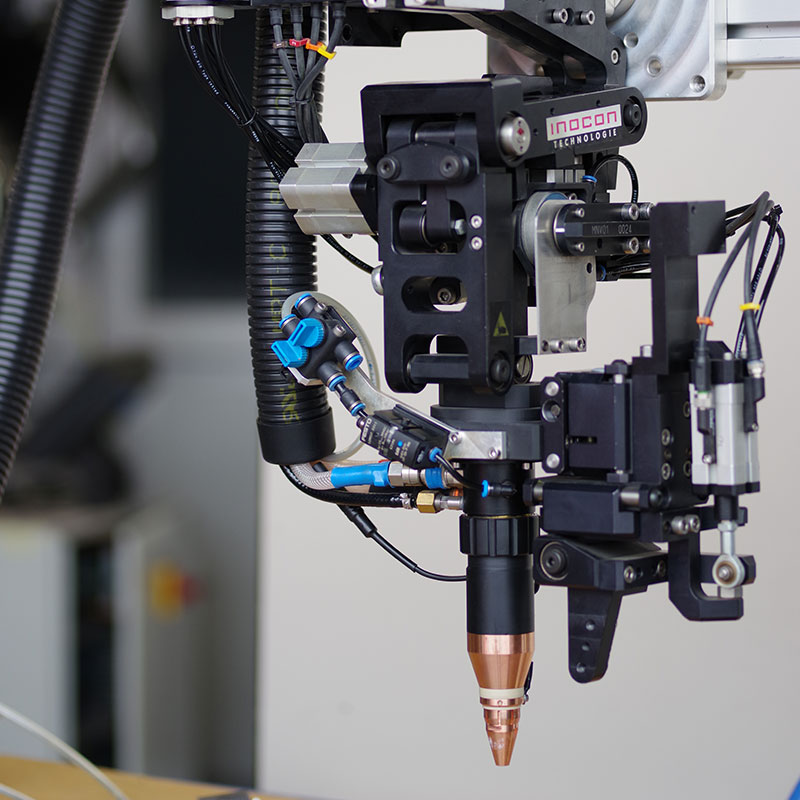

Plasmatron

Plasma

To the products

Plasmatron torch

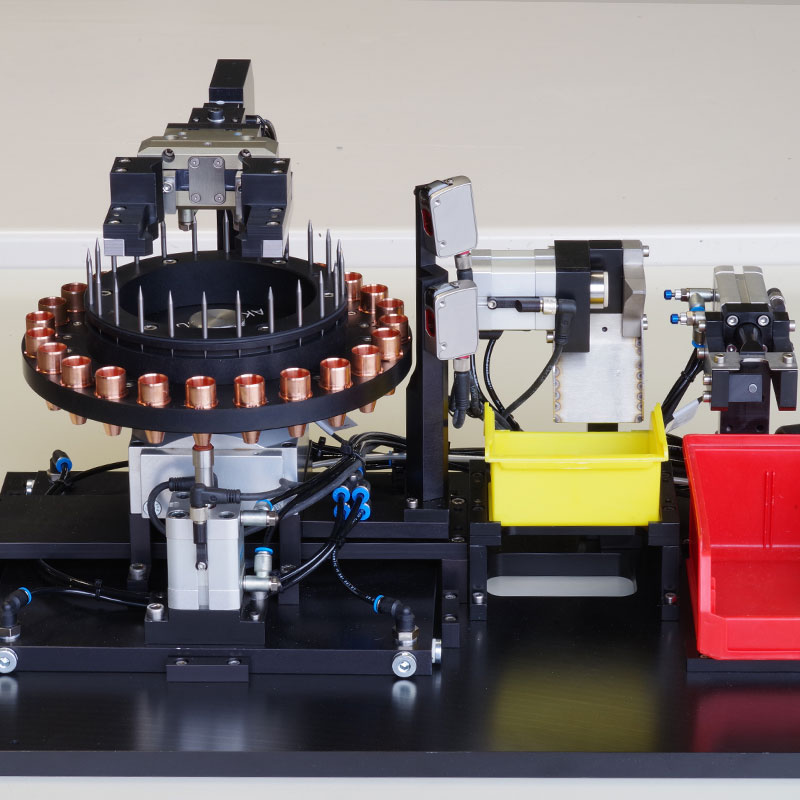

Seam guidance

Cathode changer

To the projects

If this appeals to you, send us your application and become part of our team.