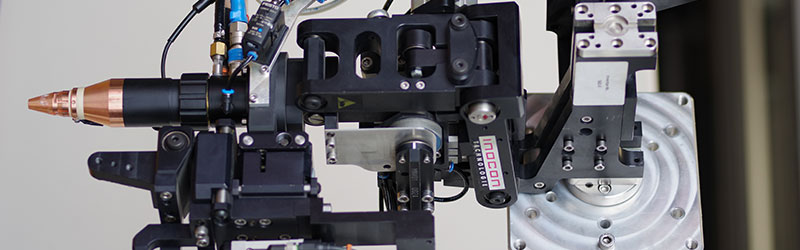

Plasmatron torch

Focussed on your success

The Plasmatron torch was developed for maximum automation capability and for use on a robot.

Using pinned components and a defined alignment, the TCP can be achieved precisely and with repeat accuracy even when the torch is changed.

A pneumatic clamping system allows quick and easy replacement of the tungsten electrode.

For production lines with very high production volumes, the electrode can also be replaced in an automatically.

The Plasmatron consists of a Plasmatron welding torch that is equipped with a nozzles set and the Plasmatron support.

The support acts as the connection to the hose package. Depending on the application, there are two different versions of the holder. (Hose package outlet either upwards or to the side)

Advantages of Plasmatron

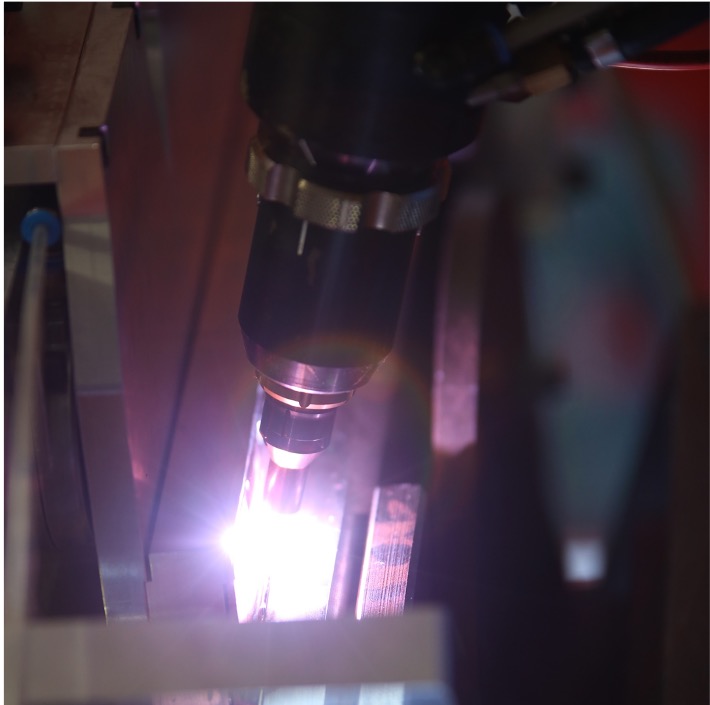

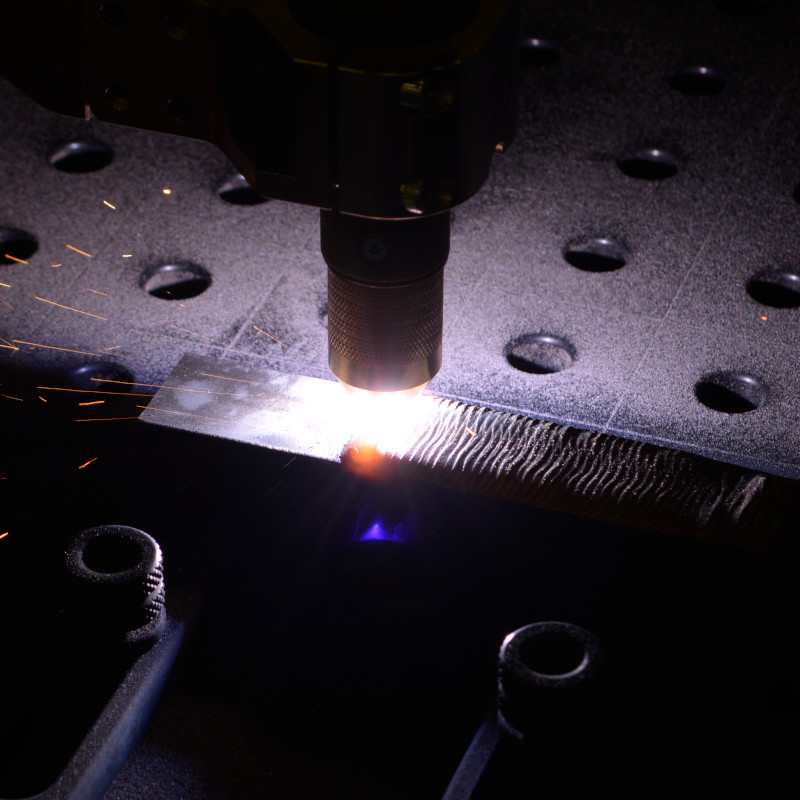

Perfect visual appearance

Technical data

Further products

Seam guidance

Cathode changer

About the procedures

Plasmatron

Plasma

MIG / MAG

To the projects

If this appeals to you, send us your application and become part of our team.