Seam guidance

Focussed on your success

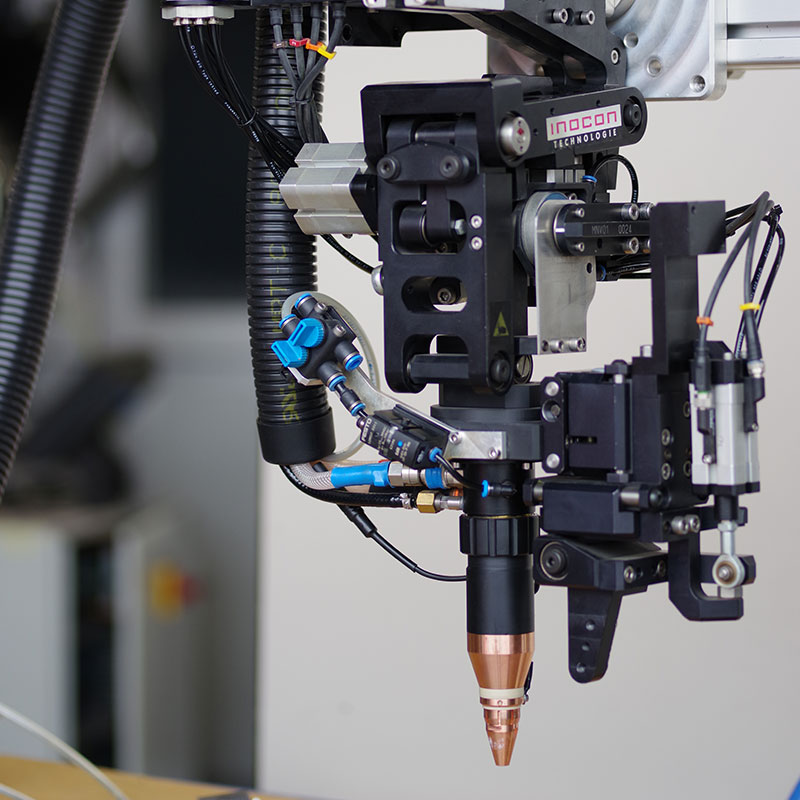

MNV stands for mechanical seam tracking and is a tactile seam guidance system.

A particularly robust and EMC-safe seam guidance system has been created by deliberately dispensing with servomotor drives.

The MNV is able to compensate for robot track and weld seam contour deviations of up to ±15 mm (vertically and horizontally). The seam contour is scanned in a tactile manner using guide elements that are optimally adapted to the respective welding task.

The guide element of the MNV is also the wire guide nozzle. Guiding the wire in a hardened nozzle permits very precise positioning of the wire.

An edge (e.g. a overlap joint) is required to guide the welding torch. The clamping forces are set using pneumatic cylinders.

Advantages

By using just mechanical components, the seam tracking system is not affected by electrical interference (ignition, earthing path, etc.).

Mechanical guidance means contamination has no effect.

Technical data

Further products

Plasmatron torch

Cathode changer

About the procedures

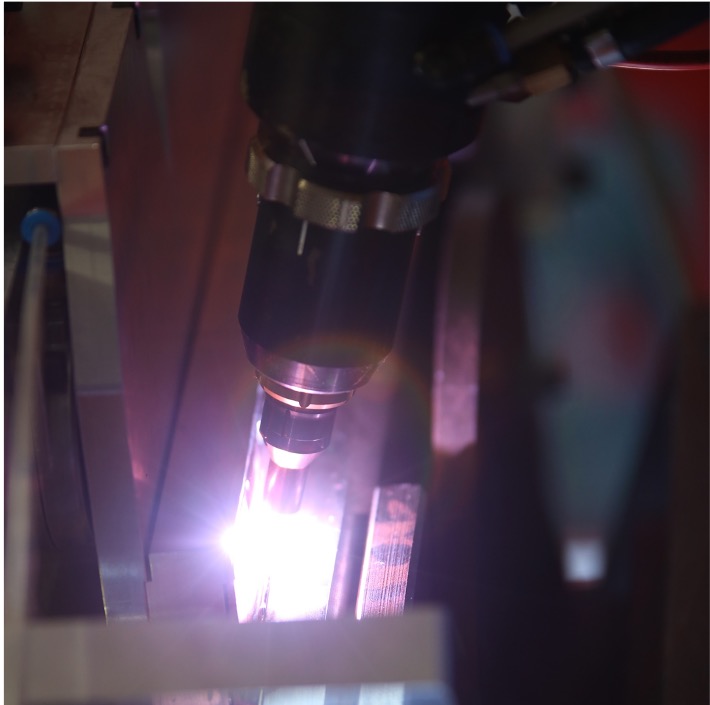

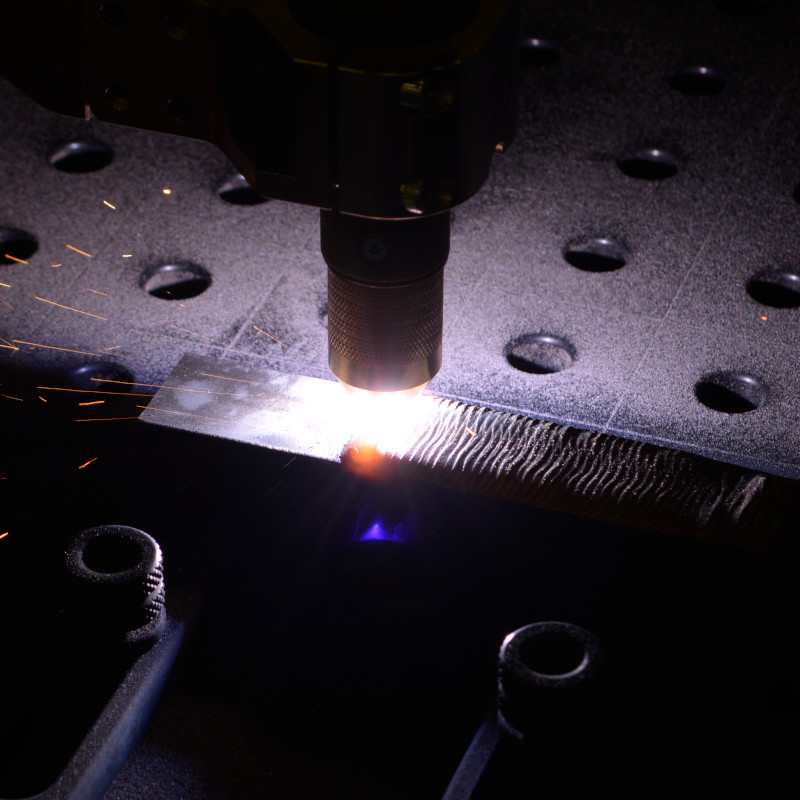

Plasmatron

Plasma

MIG / MAG

To the projects

If this appeals to you, send us your application and become part of our team.